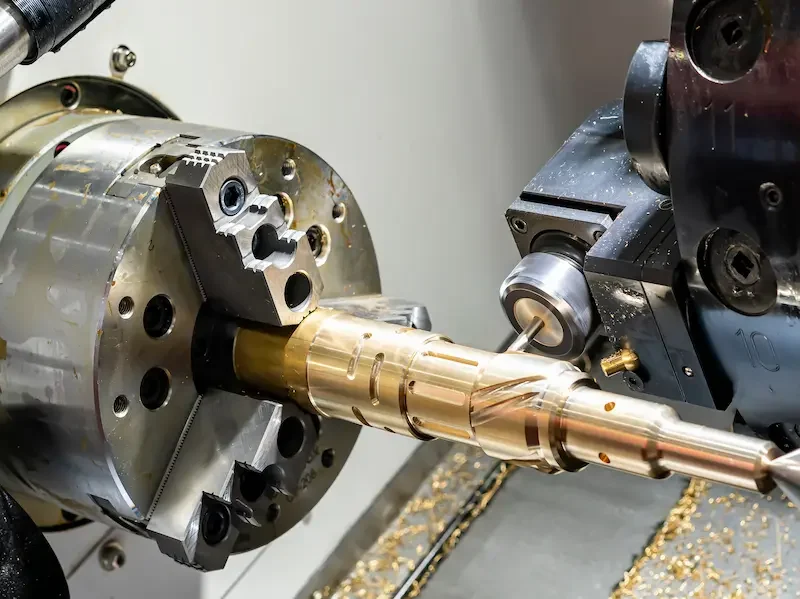

CNC machines can be a good choice for businesses looking to improve their manufacturing processes. They have many advantages, including precision, efficiency, and flexibility. CNC machining removes the risk of human error and is perfect for parts that have tight tolerances, as it produces uniform outputs.

Precision

Precision machining is an excellent choice for making parts that need to be precise and accurate. This method can produce particular parts to meet various requirements in industries, including the medical field, aerospace, defense, automotive, and more. The CNC machining processes use software programs to guide the cutting tools in the process. Based on product specifications, these programs identify optimum tool paths, finishing processes, and cycle times. This type of machining accuracy is unmatched, ensuring that the final product meets your design and manufacturing needs. This allows you to reduce the risk of internal scrap, which is costly and creates waste. Precision machining also saves prototype designs to be used in future production. This eliminates the need to re-load designs for each machine operator. This reduces the time it takes to produce replicas and ensures uniform products across the board.

Efficiency

CNC machining can be a very efficient process for manufacturers. It can help increase productivity and cut down on waste. CNC machines use a computer to create cutting programs that produce exact and accurate parts. This means that the final product can perfectly match the original prototype’s specifications and reduces the number of minor variations from human error. Another benefit of CNC machining is that it can be operated 24 hours a day, seven days a week. This is an advantage that manual machining processes can’t offer.

Moreover, it is safer to operate CNC machinery because there is less direct contact between the operator and sharp implements like lathes and drills. That makes it a more pleasant and secure environment for workers, which increases employee morale. To achieve higher efficiency, it is essential to have a work plan for each day. This plan will set realistic expectations and ensure that you meet them. It will also help you work the staff and the equipment properly.

Flexibility

CNC machining is a very flexible process that can handle various operations. This makes it an excellent choice for manufacturers who need to complete multiple tasks quickly and efficiently. Unlike manual machining, which requires humans to control the machine manually and the cutting head, CNC is automated and controlled by computer software. This reduces human error and helps make the process faster and more efficient. The flexibility of a CNC machine allows for rapid production changes, such as adding new components or changing the program to produce different types of parts. It also reduces floor space requirements. This flexibility is beneficial for small and specialty projects, where it’s essential to have a fast and accurate method of producing prototypes and products. For example, the electronics industry uses CNC machining to create a variety of small, precision-built components that need to hold to extremely tight tolerances throughout production runs.

Safety

CNC machining has several safety benefits over manual machining. These include that the machine is typically enclosed, which reduces the risk of injury. CNC machines also use less power than older machining methods, reducing energy consumption and greenhouse gases. This is especially important for companies that operate in industries where emissions are a concern. Similarly, CNC machining eliminates human errors by controlling the machining process using a computer program. This ensures that the finished product is identical, regardless of who begins the machining. The machining process can be exact, resulting in tight tolerances for diameter and fit. This is critical for the oil and gas industry, where valves and cylinders must be manufactured with consistent accuracy to control the pressure and flow of liquids. Because of the precision and speed that CNC machining requires, workers must follow specific safety guidelines when operating these machines. These guidelines include using appropriate personal protective equipment, maintaining a safe distance from the machine’s rotating parts, and keeping tools clean.