If you’re responsible for fluid flow in an industrial setting, you know how important it is to monitor that flow closely. However, it can be not easy to get an accurate reading of how much fluid is moving and where it’s going without the proper equipment. That’s where flow meters come in. A flow meter is a device that helps measure the rate of flow of a liquid or gas.

What are flow meters?

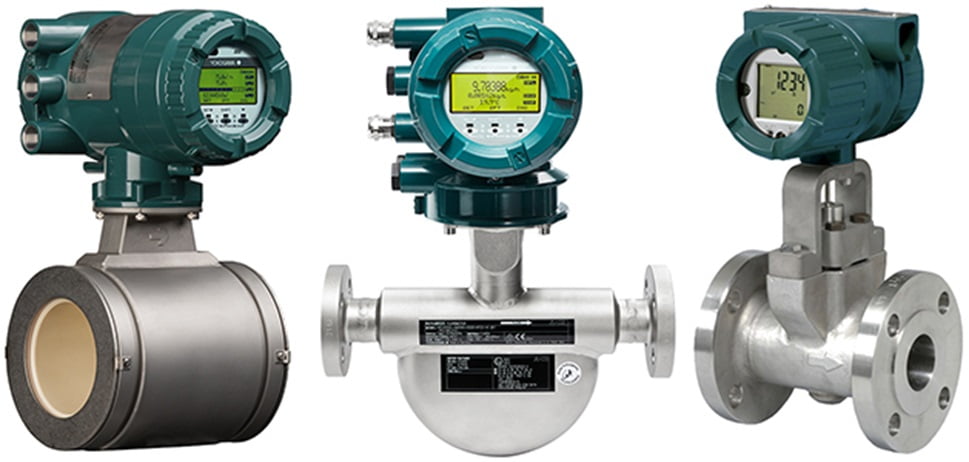

These are devices used to measure the flow rate of a fluid. They can be used in various settings, such as in industrial or laboratory settings. For example, flow meters can monitor the flow of a fluid in a pipeline or other system and help ensure that the flow remains consistent. There are several different types of flow meters, which we will discuss below.

Types of flow-meters

Positive displacement flow meters:

They work by gauging the amount of fluid displaced as it passes through the meter. They are very accurate and can measure a wide range of flow rates. However, they can be costly and require regular maintenance.

Differential pressure flow meters:

They work by measuring the difference in pressure between two points in a system. They are typically used to measure the flow rate in a pipeline or other closed system. Differential pressure flow meters are less expensive than positive displacement flow meters and require less maintenance.

Velocity flow meters:

Velocity flow meters measure the velocity of a fluid as it passes through the meter. They are typically used to measure a liquid or gas flow rate in an open system, such as in a riser or pipeline.

Mass flow meters:

Mass flow meters work by measuring the mass of a fluid as it passes through the meter. They are typically used to measure the flow rate of a gas in an industrial setting. Mass flow meters are very accurate but can be expensive.

How beneficial are flow meters?

Improve safety:

The main benefit is that they help improve safety in industrial settings. Flow meters can monitor the flow of hazardous materials, such as chemicals or oil, and can help prevent accidents.

Save money:

They can be used to optimize production processes and reduce wastage. For example, if you know exactly how much fluid flows through a pipe, you can adjust the flow rate accordingly to avoid overuse or leaks.

Conserve resources:

They help save money by conserving resources. Flow meters can monitor the flow of water or other fluids in a system and can help reduce the amount of water that is wasted.

Help improve efficiency:

They can monitor the flow of a fluid in a system and help ensure that the flow remains consistent. This helps avoid disruptions in the production process and helps improve overall efficiency.

Reduce emissions:

Another way that flow meters help improve efficiency is by reducing emissions. They monitor the flow of a gas or other fluid in an industrial setting and can help reduce emissions from production processes.

Wide range of applications:

They have a wide range of applications in industrial settings. They can be used to monitor the flow of fluids, gases, and other materials. Flow meters can be used to improve safety and efficiency and conserve resources. With so many benefits, it’s no wonder that these meters are an essential part of many industries.

Overall, industrial flow meters improve safety measures for workers and provide valuable data about fluid levels within pipelines so that production may continue uninterrupted if there is ever leakage or interruption during operations. With these benefits in mind, it’s no wonder why flow meters have become more popular among businesses over time!